More about cleanroom classification:

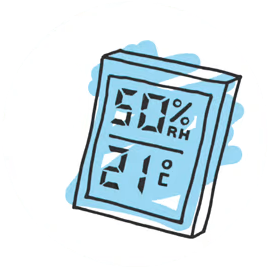

Regulating the concentration of airborne particles prevents contamination by minimising particles and microbes entering, remaining and multiplying within the space. Cleanrooms may also control other environmental factors like temperature, humidity, and light levels as needed.

Relationship between Contamination and Cleanroom Classification

Cleanrooms must be designed, constructed, and operated according to the cleanliness classification defined in ISO 14644-1:2015.

The classification required depends on the specific tasks performed within that cleanroom. Products that are highly susceptible to contamination need cleaner spaces. Once a classification is determined, the cleanroom must be maintained to meet the appropriate specifications for environmental factors such as:

- Cleanliness

- Temperature

- Humidity

- Pressure

- Number of air changes per hour

- Flow rate

When a cleanroom is constructed in a pristine environment using non-particulate materials, airflow is the primary influence on its cleanliness. Depending on the ISO class, a cleanroom will require between 5-580 air changes per hour to keep particulate levels consistently low.

Impact of Particle Size on Classification

The ISO class required depends greatly on the size of allowable particulate matter. This is the diameter of the particle measured in microns or micrometres (µm). Particulate matter is sometimes abbreviated to PM, with the diameter indicated numerically, e.g. PM5 refers to particulate matter greater than or equal to 5µm across.

For example: if a customer requires a cleanroom with fewer than 1000 particles per m3, they may opt for an ISO 6 cleanroom, as this requires less than 293 PM5/m3. However, ISO 6 allows up to 8,320 particles of 1 micron across, and 1,000,000 particles of 0.1 micron across (PM0.1).

Mistakenly classifying based on the wrong particle size would lead to inadequate cleanliness, so it is important to know what sizes of particles would cause contamination in your application.

Similarly, mistakenly identifying particle sizes when verifying cleanroom classification can cause errors. Mistaking 0.5-micron particles for 5-micron particles could mean the difference between ISO 5 and ISO 8, so the decimal place on an air quality meter is crucial to correctly classifying spaces.

Positive vs Negative Pressure in Cleanrooms

Most cleanrooms use positive pressure to keep contaminants from entering the room.

- Air is introduced through a fan-powered filter to remove particles, creating a slightly higher air pressure inside the cleanroom than outside.

- The air and any contaminants generated within the room are pushed down to the floor level, where vents allow them to flow out to the exterior.

- The pressure keeps most contaminants from entering through vents or when the door is open.

Negative-pressure cleanrooms are used to isolate substances, fumes or particles created during internal processes such as medical research or pharmaceutical development. This protects the space outside the enclosure.

- A fan pulls air and contaminants out of the room through a filter.

- This creates negative pressure inside the room, drawing new air in through venting.

- The force of air entering the room prevents contaminants from escaping.

Negative-pressure cleanrooms usually form part of a layout with multiple cleanrooms, with an anteroom immediately outside that is maintained at a higher pressure. This allows researchers to enter and exit without disrupting the environment.

Independent Cleanroom Classification

We require independent inspections and testing before use to verify that the cleanrooms we build are operating at the required classification. Read more about this on our Cleanroom Validation information page.